Why is blade steel hardened

The principle of hardening is that a blade is heated again after the previous work steps and then cooled down in a shock-like manner. This changes the internal structure of the steel and makes it much harder.

Without the hardening of the sword blade, it would not be nearly as strong and durable. For this reason, we have dedicated an extra article to this important step in sword forging. Here we will look at how and why swords are hardened.

What does heat treatment mean?

Heat treatment is the umbrella term for how a blade is treated by heating and cooling. This is extremely important for the properties of the finished blade!

Different materials require different treatments. While the heat treatment of Tamahagane and the most Industrial steel is comparatively uncomplicated, there is steel whose heat treatment is so complex that it is almost impossible to master, as is the case with L6 steel.

What is differential hardening and why is it used?

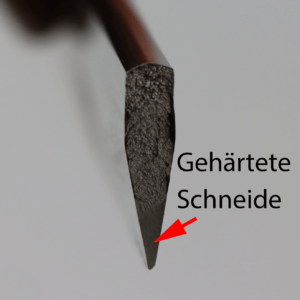

The hardening of sword blades plays an important role, as the sword edge has to withstand completely different challenges than the rest of the sword blade. For this reason, differential hardening has become established for Japanese swords. The blade is not hardened evenly, but differently. This leads to a high degree of hardness in the areas of the cutting edge where it is needed and thus creates the properties that are crucial for a sword blade.

The balance between hardness and flexibility of the blade is extremely important. A blade with a soft back and a hard cutting edge is desirable. This ensures that the sword does not break easily despite a hard blade and that the blade can be sharpened and retain its sharpness for as long as possible.

The classic for samurai swords: traditional differential hardening with clay hardening

Differential hardening using a clay coating, also known as clay hardening, is a traditional Asian method of bringing steel to the desired condition. An unhardened sword blade is coated with a mixture of clay, water, charcoal ash and finely ground whetstone. The cutting edge area of the blade is coated relatively thinly with the clay mixture, while the rest of the blade is coated relatively thickly.

The sword blade is then heated again in the clay casing until it reaches a temperature of around 800ºC to 900ºC. It is then shock cooled in a water or oil bath. As the clay coating is thinner on the cutting side, this area cools down faster than the rest of the blade. The rapid cooling ultimately produces the desired result: a higher hardness on the cutting edge than on the rest of the blade. From a visual point of view, clay hardening has the effect on most types of steel that the Hamon at the transition from the cutting edge to the body.

Water vs. oil when quenching the blade steel

Historically, there is a whole range of possible liquids that can be used to cool the hot sword steel. Some sources even report that real blood was used for this purpose.

Nowadays, in addition to simple cooling in the air, water, various oils or acid baths have become established in sword forging.

Steel cooled in the air usually cools down very slowly, in contrast to water, where the steel loses its temperature comparatively quickly, even with boiling water. The advantage of oils is their higher boiling range. This makes it possible to cool the steel slowly but in a controlled manner.

Which process is used depends largely on the steel used and the desired properties.

Importance of the temperature of the extinguishing medium

With any form of hardening, the temperature of the quenching medium plays a decisive role in the properties of the end product. If the quenching medium is too cold, the steel cools down very quickly, which would have a negative impact on the resistance of the blade. If the medium is too warm, the steel cools down too slowly, which would impair the strength of the blade.

Differential hardening vs. differential tempering

In general, the differential heat treatment of sword steel can be divided into 2 different methods. On the one hand, as with clay hardening, the entire blade can be heated and then cooled. The clay coating causes the steel to cool at different rates, resulting in both martensite (hard) and pearlite (softer).

The other method is to heat the sword blade without clay coating and then cool it down. This turns the steel uniformly into martensite. A part of the blade is then heated to a significantly lower temperature, which results in this part of the blade becoming softer. This second process is called differential tempering.