The construction of the blade is an important criterion for the price of a samurai sword blade. The more different hardnesses are forged together, the more expensive it is to produce.

But does a complicated structure have advantages or is it just unnecessarily expensive? We will explore this question in this article.

Why is there a specific blade construction for the samurai sword blade?

A legitimate question, because it would be enough to always produce a samurai sword blade with the simplest blade construction (Maru). However, the use of steel with different hardnesses used to be mandatory:

Tamahagane steel with a high carbon content is very hard, but also brittle. For historical Nihonto blades, it was important to use different hardnesses. A blade made only of hard tamahagane would break very quickly. Especially when struck against hard armour.

In battle, blade designs such as Kobuse had the advantage that the sword did not break immediately if the hard layer was damaged, but was still "held together" by the soft core.

It was also possible to parry with the soft back of such blades without damaging the layer on the cutting edge.

A positive side effect of blade designs is the use of steel of varying quality. Japanese history was also characterised by a lack of good quality steel. With special blade designs, less high-quality metal could be used for the soft components and the expensive, high-quality material could be used in the right place.

These advantages apply to blades made of Tamahagane steel and not to blades made of modern industrial steel! Why this is the case is explained below.

Examples of a complex blade design for a samurai sword

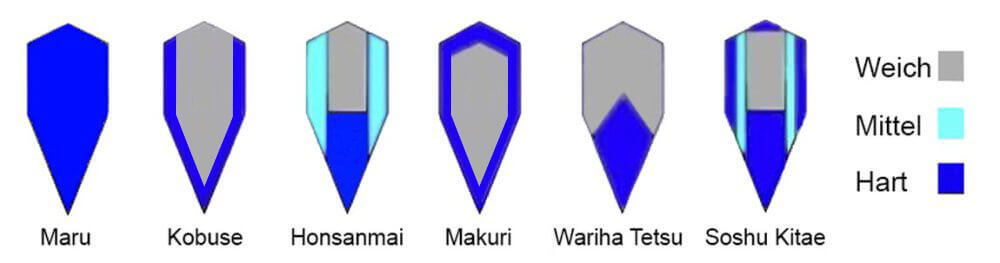

We show frequently used construction types here. There are many ways to construct a blade, but the principle should be clear from these examples:

Maru

Maru is the simplest blade construction for a samurai sword blade. It is the most sensible and cost-effective construction for blades made of modern industrial steel.

Kobuse

The Kobuse blade construction has two different degrees of hardness. An outer hard steel layer and a soft core. It is the standard construction for swords made from Tamahagane steel.

Honsanmai

The Honsanmai blade type is one of the most common blade designs. It has 3 different degrees of hardness. The inside of the blade is soft, the cutting edge is hard and the outer layer has a medium degree of hardness compared to the other two. With this construction, it should be borne in mind that the medium-hard outer layer can scratch relatively quickly during cutting tests.

Makuri

The Makuri blade type is a relatively simple construction, as a soft iron core is completely surrounded by a hard steel sheath.

Wariha Tetsu

The Wariha Tetsu blade type is a construction consisting of two degrees of steel hardness. The cutting edge of the blade is hard, while the rest of the blade is made of a softer metal.

Soshu Kitae

The Soshu-Kitae blade type is one of the more elaborate designs with several steel hardness grades.

Why have so many blade designs evolved and why do they still exist today?

The blade designs used to have a number of advantages, as described above. The old sword schools therefore created increasingly complex blade structures in order to maximise the properties of the blade. of the old swords to be improved. Blade designs were sometimes even the distinguishing mark of individual sword schools.

Nowadays the law in Japan is that swords may only be made according to old traditions. Steel such as Tamahagane steel must therefore be used and this requires a complex blade construction for a usable sword. For this reason, swords made from tamahagane are usually forged in kobuse form and the old blade designs are used for swords forged in Japan. Shinsakuto continue.

With blades made of modern industrial steel, a complex blade structure usually brings no advantages and only causes unnecessary costs.

What is the difference between different steel in Damascus steel and the blade constructions

One question that is often asked by customers is what the difference is between a Damascus steel blade and a blade with a specific blade construction.

With Damascus steel, a packet of different types of steel is first folded, then folded further, ... and finally this packet is forged to length.

Swords with a specific blade structure, on the other hand, are often made from just one type of steel with a different carbon content. The individual elements are not combined by folding, but "only" joined and then forged together to achieve the final length of the sword.

Blade construction for medium-priced swords

Medium-priced swords (everything up to approx. 2000 euros) are usually made of industrial standard steel. You can find a short list of examples of industrially manufactured steel grades in this Article about steel grades.

Some sellers of these swords suggest that a blade with a complicated blade construction has better properties than blades with a simple construction. However, the exact opposite is usually the case!

Today's steel is much more flexible than the old types of steel from back then.

There is only a small risk that a real Maru blade made of modern steel will break. Unless you hit too hard targets with soft steel, for example with 1045 carbon steel on metal.

With modern swords made of industrial steel, an elaborate blade design is generally unnecessary. Provided the right steel is used.

If a blade made of industrial steel is to be used for cutting tests, we recommend the Maru structure in combination with a suitable steel, for example 1060 carbon steel or spring steel! Modern steel does not break so quickly due to its components. If soft steel is also used, this increases the risk of the blade bending during cutting tests. In addition, similar to the Number of foldsthat the more elaborate construction significantly worsens the risks to the quality of the blade if the workmanship is not clean.

So don't let false information take money out of your pocket unnecessarily.

You can find swords at reasonable prices in our Shop.

Video about the topic: