What does hardness mean?

The hardness, such as the HRC hardness, of a material is technically the resistance that a material offers when another material penetrates it.

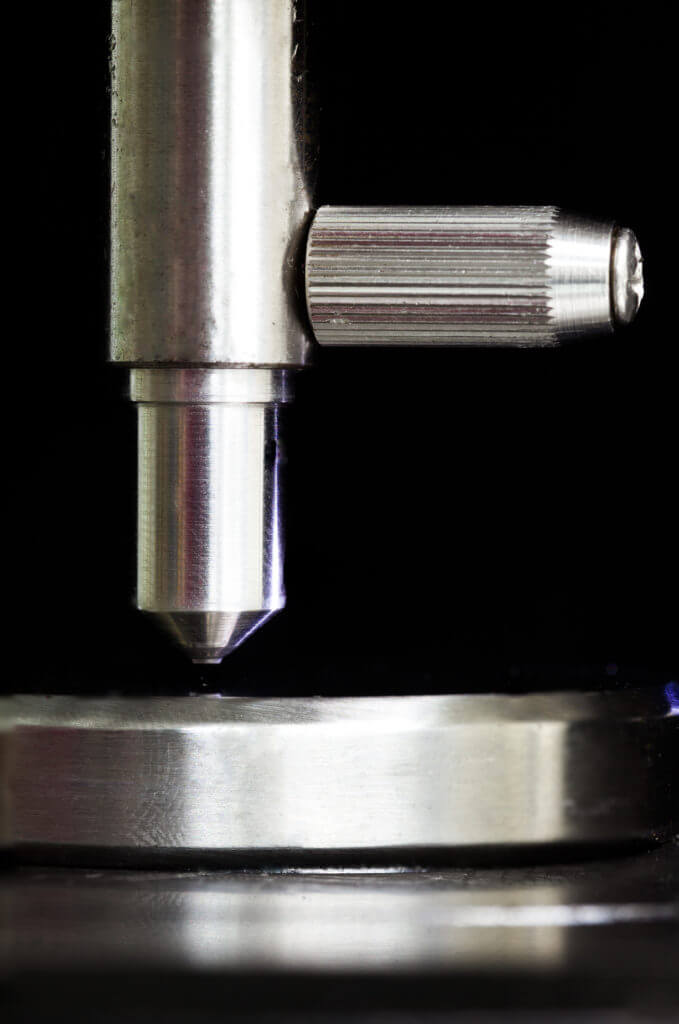

There are various methods for determining the hardness of a material. As a rule, a very hard material (e.g. diamond) is used to penetrate a softer material (e.g. steel). The effect on the softer material then gives an indication of its hardness.

Measuring method according to Rockwell & HRC hardness

The Rockwell measuring method is generally used for blades and knives. Its result is given in the unit HR. As sword steel is relatively hard, the C scale method is used. The result is therefore given in the unit HRC.

To put it simply, a cone-shaped diamond is driven into the steel to measure how deep the diamond penetrates.

Typical values for blades

Blades usually have a value between 40 and 65 HRC.

A hardness of 60 is already a decent value and at over 62 HRC the air becomes thin, as most sword blades have a lower HRC value. Only very few reach a value above 65 HRC.

For orientation: The hardness of a stainless steel knife blade is usually around 50 HRC.

Incidentally, the Rockwell method only allows values in the range between 20 and 70 HRC. So there is no value above 70 HRC!

Important addition

It is not a rule that the steel with the higher HRC hardness value is the better steel for a blade. It depends very much on which steel is used. Some types of steel are very hard but brittle and are therefore not suitable for blades.

The HRC value is often given as a guide. However, a sword blade should never be judged by this one value alone.

You can find more information on the individual types of steel used for swords in our article Blade steel types of Samurai swords.